Per-and polyfluoroalkyl substances (PFAS), chemicals with a devastating fusion of longevity and toxicity, highlight the hole at the center of the “chasing arrows” recycling symbol. Discussions of a zero-waste or circular economy often fail to account for the ‘forever chemicals’ that fall in rain, taint waters and soils, and infiltrate bodies.

A world of dwindling resources demands that we move toward systems of resource recovery and reuse that require fewer materials and generate minimal waste. States like Maine and Oregon, with pioneering extended producer responsibility (EPR) laws, are pushing essential change in how we design, manufacture and reuse material goods.

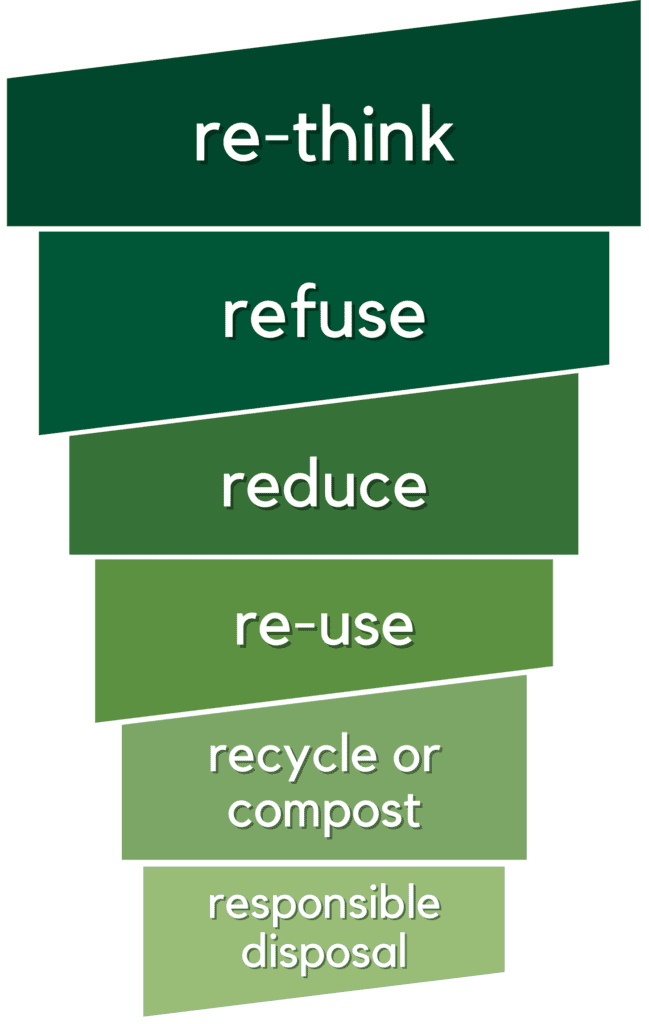

But PFAS are an omnipresent reminder that we must also rethink what goes into those goods.

Thwarting circularity

Recycling and composting of organic wastes are predicated on the assumption that the constituent materials will break down — as happens in nature with the decomposition of wood, leaf litter and other organic matter. Countless synthetic materials now in our households, bodies and waste streams — from PFAS and PCBs to microplastics and flame retardants — don’t readily degrade and can cycle through ecosystems for generations.

The PFAS permeating Maine soils and waters came in part from sewage sludge, a byproduct or “side stream” of municipal wastewater management. Those systems were designed to treat biological material not to remove harmful chemicals.

The problem has to be addressed upstream of wastewater treatment. “To reduce the problems associated with PFAS in sewage sludge in both the circular economy and in the urban water cycle…,” a briefing note published last July by 35 national water services associations in Europe concluded, “it is necessary to restrict and phase out all PFAS.”

Maine reached the same determination in 2021 and is working toward a full ban on PFAS by 2030. But these compounds will remain in the waste stream long after that date — as they continue to wear off materials and accumulate in leachate (rainwater and snowmelt that has percolated through landfills).

“We can’t circularize sludge when we produce and use toxic chemicals that get in the water,” explained Jean MacRae, an environmental engineer at the University of Maine. But absent the historic choice of land-spreading sludge, a torrent of troubles arise for those who manage wastewater treatment plants, landfills and environmental agencies.

Maine is at the forefront of contending with the implications of PFAS in the waste stream, a challenge no state will escape; “In the long run, it’s going to be good for Maine to have done this [work],” MacRae observed.

We can’t filter our way out of this problem

While Maine has banned land spreading of sludge and sludge-based compost, it has yet to fully address another PFAS-laden side stream, septage, the residuals pumped from private septic systems that are currently either land-applied or trucked to wastewater treatment plants.

According to a January update the Maine Department of Environmental Protection (DEP) provided to the Legislature, 10 percent of septage is still land-applied. Transporting that remaining septage to wastewater treatment plants with the capacity to accept them poses challenges, especially in northern Maine where one-way transport would average 98 miles.

More septage going to wastewater treatment plants generates more sludge, much of which is now being transported to landfills. That’s causing growing concerns about landfill stability and about the volume of toxic leachate being generated — none of which currently gets treated for PFAS.

Last year, the Legislature called for a study of leachate treatment options, seeking to stop PFAS-laden leachate generated at two state-owned landfills, Juniper Ridge in Old Town and Dolby in East Millinocket, from entering wastewater discharged into the Penobscot River.

The preliminary report, delivered in January, recommends treating leachate at both facilities using “foam fractionation,” where air bubbles generate a surface foam. PFAS, being surfactants, are drawn to that interface and collect in the foamate.

The process avoids added chemicals and high inputs of energy, but the resulting foamate becomes a side stream of concentrated PFAS that must itself be treated. That would likely involve either adsorption onto a medium returned to the landfill (where leachate generation would begin anew) or electrochemical oxidation, a process still being refined and only economical at a small scale.

Another means of treating leachate and drinking water involves granular activated carbon filters, which capture much of the PFAS routinely tested for. These filters have helped remediate drinking water in many Maine homes, businesses, schools and water utilities, but the spent filters become another side stream carrying PFAS to landfills or incinerators.

Municipal incinerators don’t achieve the extremely high temperatures that might fully break down PFAS, and at lower temperatures the compounds can remain intact or reconstitute into other harmful chemicals before being released into the atmosphere. Research is underway at the University of Maine and elsewhere to break down the PFAS captured in filters, but it could be years before any such technology is readily available.

Getting a wide-angle view

Maine’s wastewater treatment community has worked hard to adapt to the ban on land-spreading sludge, and situations like the February decision by Casella Waste Systems to decline sludge deliveries have only made that transition harder. With a byproduct that accumulates daily and dwindling options for disposal, wastewater utilities can’t find alternatives quickly enough.

Seeking better long-term answers, the Maine Water Environment Association (MEWEA) decided to commission a comprehensive engineering study that could help utilities of various sizes determine their best options for reducing sludge and septage volumes and for sound disposal.

Their choices rest in part on knowing what “physical and operational capacity” exists at landfills, said Travis Peaslee, general manager of the Lewiston-Auburn Water Pollution Control Authority and a MEWEA board member. “We’re at the mercy” of landfill operators, he added, and even state-owned facilities “are essentially private operations.”

The Maine DEP joined MEWEA in developing the scope of work and committed to pay the national engineering firm Brown and Caldwell to undertake the study. Building on work done to date by the state and a smaller consulting firm, the study will look at managing landfill leachate, as well as sludge and septage. Results are expected by the end of the year.

“I’m kind of hoping this study spits out some answers,” Peaslee said, helping different utilities better understand “how these pieces fit together statewide.” Measures to reduce sludge and septage volumes, such as improved dewatering, drying, and anaerobic digestion “will help us with the landfill crisis,” he added, and drying is likely a “necessary pre-step to any future PFAS treatment.”

Sequestering PFAS-laden waste in landfills is probably the best option for now, MacRae believes, but only as an “interim solution.” The faster Maine can learn from manufacturers what’s in their products, the easier it will be to handle those goods responsibly (or eliminate their use). But with thousands of PFAS, only a few dozen of which are tested for, “there are a lot of complicating factors we’re not really looking at,” MacRae observed, and an “unknown suite of effects on the environment.”

Moving toward a circular economy requires ensuring that the constituent elements of what we produce are not persistent hazards, which will entail tradeoffs in what we manufacture and use. Perhaps going forward, we’ll do a better job weighing those tradeoffs before chemicals are widely disseminated, rather than decades later.

The ongoing struggle to contend with PFAS contamination could foster an ecological foresight we’ve lacked until now: “We don’t really think about what the outcome is going to be,” MacRae reflected, nor do we “think about the system in the right way.”